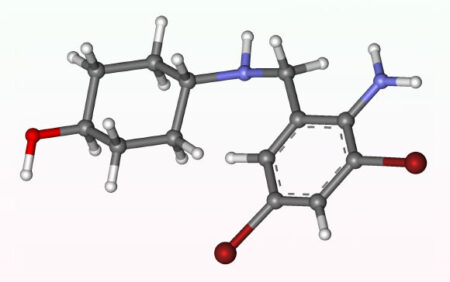

This cardboard-based foam reinforced with gelatin has the potential to make packaging materials more sustainable.Credit: Gou Jingsheng

Eco-friendly cushion foam made from recycled cardboard provides a stronger, more insulating alternative to traditional packaging materials, providing a sustainable solution for the shipping industry.

The holiday season is in full swing and gifts of all shapes and sizes are being shipped all over the world. However, all packaging generates large amounts of waste, including cardboard boxes and plastic-based foam cushioning such as his Styrofoam™. Rather than throw those boxes away, researchers ACS Sustainable Chemistry and Engineering We developed cushion foam from cardboard waste. Their upcycled material was stronger and more insulating than traditional plastic foam-based cushions.

Turn common household waste into eco-friendly materials

Out of all the types of trash that accumulate in your home, paper waste is one of the most common. Especially as internet shopping has exploded in popularity, everything from newspapers and junk mail to cardboard envelopes and boxes can end up piling up. Researchers are interested in turning these containers and paper scraps into something else useful: durable, lightweight mail.

Today, molded cushioning materials such as Styrofoam are typically used to securely fit electronics and toys inside boxes. Lightweight cellulose aerogels are a possible sustainable alternative, but current methods of producing aerogels from waste paper require several chemical pretreatment steps. So Jinsheng Gou and colleagues wanted to find an easier way to create a waste paper-based foam material that could withstand even the toughest deliveries.

Innovative cardboard-based foam for added protection

To create the foam, the team crushed cardboard scraps in a blender to create a pulp, which they mixed with either gelatin or polyvinyl acetate (PVA) adhesive. The mixture was poured into molds, refrigerated, and then freeze-dried to form cushioning foam. Both paper-based foams acted as excellent insulators and strong energy absorbers, even better than some plastic foams.

The team then created a durable version of the wastepaper foam by combining pulp, gelatin, PVA adhesive, and a silica-based liquid that hardens when force is applied. This version’s cardboard-based foam withstood hammer impact without shattering. The results suggest that the foam could be used for deliveries that require force, such as airdrops without a parachute.

The researchers say their work provides a simple and efficient way to upcycle cardboard to create more environmentally friendly packaging materials.

Reference: “Biodegradable waste paper-based foam with ultra-high energy absorption, good insulation and good cushioning properties” Bin Zhang, Wenxuan Tao, Ziming Ren, Shiqi Yue, Jinsheng Gou, November 28, 2023 Day, ACS Sustainable Chemistry and Engineering.

DOI: 10.1021/acssuschemeng.3c06230

The authors acknowledge funding from the Beijing Key Research Institute of Wood Science and Engineering.

Source: scitechdaily.com