In a groundbreaking achievement in the field of medicine, a 3D printed organ has been successfully transplanted into a patient for the first time in history. A South Korean patient is currently recovering with a new trachea partially made from someone else’s stem cells.

The pioneering 3D-printed trachea transplant took place at Seoul St. Mary’s Hospital in 2023, led by a team of scientists, doctors, and engineers. The recipient was a woman in her 50s who had lost part of her trachea following thyroid cancer surgery.

While 3D printed bones and food have shown some success, the transplantation of organs marks a new frontier in medical technology.

What is the 3D printed trachea made of?

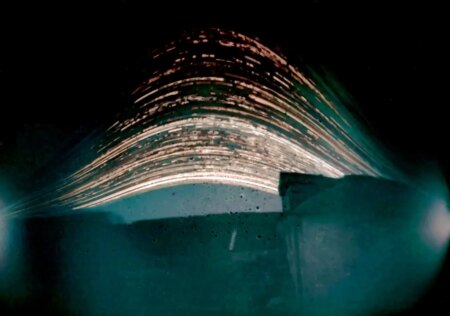

The patient’s new trachea is composed of cartilage and mucosal lining, sourced from nasal stem cells and chondrocytes obtained from other patients. The bioink used also contains polycaprolactone (PCL) for structural support, different from the standard ink used in home printers.

Given its biodegradable nature, PCL has a limited lifespan of about 5 years. However, researchers hope that within this timeframe, the artificial organ will stimulate the patient’s body to regenerate its own windpipe.

According to the hospital, traditional treatments post-tracheal resection do not allow for restoration of the original organ and can be complex and risky. The introduction of 3D printed organs could transform the treatment of patients with thyroid cancer, congenital defects, and tracheal trauma.

Significantly, patients undergoing this procedure did not require immunosuppressants. At the six-month mark post-surgery, the patient’s trachea was healing well with the development of new blood vessels.

The research is currently undergoing peer review for publication in a scientific journal.

How do I 3D print a trachea?

The dimensions of the trachea must be customized for each patient based on their CT and MRI data. In this particular case, the trachea’s length needed to be under 5 cm (2 inches).

The printing process took less than two weeks, and the implantation occurred during a half-day surgery.

The successful collaboration behind this procedure involved the Catholic University of Korea, Gachon University, and T&R Biofab, the biomedical engineering company responsible for manufacturing the printer.

This achievement is the culmination of two decades of research, dating back to 2004 with preliminary laboratory studies on animals such as beagles. T&R Biofab’s specially designed printer enabled the creation of personalized, hollow, tubular organs with high precision technology.

Although the printer was tailored for Seoul St. Mary’s Hospital, there is potential for future expansion beyond this specific institution.

Dr. Paulo Marinho, Head of Science Strategy at T&R Biofab, expressed optimism about the future of 3D bioprinting technology and its potential to address organ shortages for transplantation.

About our experts

Dr. Paulo Marinho, with a background in chemical engineering and postdoctoral experience in regenerative medicine, plays a crucial role at T&R Biofab in advancing the frontiers of 3D bioprinting.

Read more:

Source: www.sciencefocus.com