Miniature chairs and tables 3D printed from scrap wood

Thakur et al., Sci. Advanced 10, eadk3250 (2024)

Recycled wood can be turned into ink for 3D printing, potentially providing more sustainable ways to manufacture furniture and build homes.

“Wood has been used for architectural and structural purposes for centuries,” he says. Muhammad Rahman At Rice University, Texas. However, processing the material is not very efficient as engraving the material to size can result in a large amount of waste.

To utilize this leftover material, Rahman and his colleagues split it into lignin and cellulose (key molecules in wood’s hard structure) and broke these down to form nanofibers and nanocrystals. . The cellulose and lignin were then recombined with water to create a clay-like substance that could be used as an ink.

The researchers used this material to 3D print objects by forcing it through a nozzle and building up layers of ink.

To increase the strength of the 3D printed objects, the team freeze-dried them to remove water, then immediately heated them to 180°C (356°F) to soften the lignin and fuse it with cellulose. Ta.

“In fact, we can mimic all the visual, textural and olfactory properties of natural wood,” says Rahman. The product was found to be approximately six times more durable than natural balsa wood in compression tests and up to three times more durable in bend tests.

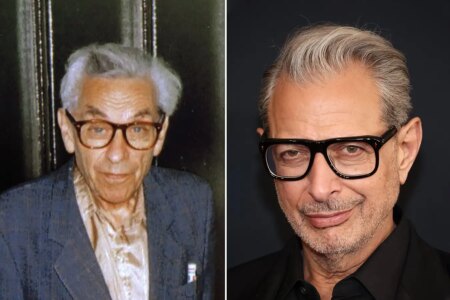

So far, researchers have been able to use the ink to create miniature furniture and honeycomb structures, but they hope it could eventually be used to build larger objects such as houses. ing.

“We need to rethink how we build structures without cutting down trees,” Rahman says. “If instead of traditional manufacturing he could use 3D printing to recycle waste wood, that would be a good step forward.”

topic:

Source: www.newscientist.com