Niobium phosphide conducts electricity better than copper in films a few atoms thick. What's more, these films can be created and deposited at low enough temperatures to be compatible with modern computer chip manufacturing, according to a team of scientists led by Stanford University.

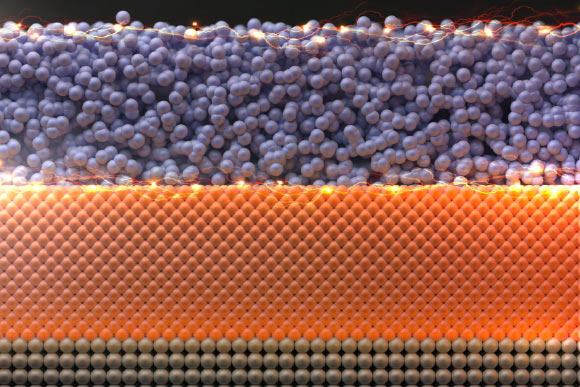

Amorphous niobium phosphide films a few atoms thick have better surface conductivity, making the entire material a better conductor. Image credit: Il-Kwon Oh / Asir Khan.

“We are breaking the fundamental bottlenecks of traditional materials like copper,” said Dr. Aseel Intisar Khan of Stanford University.

“We show that our niobium phosphide conductor can transmit signals faster and more efficiently through ultra-thin wires.”

“This could make future chips more energy efficient, and even small gains can add up when large numbers of chips are used, such as in large data centers storing and processing today's information. There is a possibility.”

Niobium phosphide is what researchers call a topological metalloid, meaning that the entire material can conduct electricity, but its outer surface is more conductive than the center.

As a film of niobium phosphide becomes thinner, the central region shrinks, but its surface remains the same, allowing the surface to take a greater share in the flow of electricity, making the entire material a better conductor. .

Traditional metals such as copper, on the other hand, become less conductive when thinned below about 50 nm.

The researchers found that niobium phosphide is a better conductor than copper at film thicknesses of 5 nm or less, even when operating at room temperature.

At this size, copper wire has a hard time handling rapid electrical signals and loses more energy to heat.

“Really high-density electronics requires very thin metal connections, and if those metals don't conduct well, you're going to lose a lot of power and energy,” said Eric Popp, a professor at Stanford University. said.

“If we had better materials, we could spend less energy on thin wires and more energy on actual calculations.”

Many researchers have been working to find better conductors for nanoscale electronics, but so far the best candidates have very precise crystal structures, which can be used at very high temperatures. must be formed with.

The niobium phosphide film the researchers created is the first example of an amorphous material that becomes a better conductor as it becomes thinner.

“It has been thought that if you want to take advantage of these topological surfaces, you need good single-crystal films that are very difficult to deposit,” said Akash Ramdas, a doctoral student at Stanford University. .

“Now we have another class of materials, topological metalloids, that could serve as a way to reduce energy usage in electronics.”

Niobium phosphide films do not need to be single crystal, so they can be made at low temperatures.

The scientists deposited the film at 400 degrees Celsius (752 degrees Fahrenheit). This temperature is low enough to avoid damage or destruction to existing silicon computer chips.

“If you have to make a perfect crystalline wire, that doesn't work in nanoelectronics,” says Yuri Suzuki, a professor at Stanford University.

“But if you can make them amorphous or slightly disordered and still give them the properties you need, that opens the door to potential real-world applications.”

The authors are also working on fabricating the niobium phosphide film into thin wires for additional testing.

They want to determine how reliable and effective the material is in real-world applications.

“We've taken some really cool physics and transplanted it into the world of applied electronics,” Professor Popp said.

“This type of breakthrough in amorphous materials could help address power and energy challenges in current and future electronics.”

of work Published in a magazine science.

_____

Asil Intisar Khan others. 2025. Surface conduction and electrical resistivity reduction in ultrathin amorphous NbP semimetals. science 387 (6729): 62-67;doi: 10.1126/science.adq7096

This article is a version of a press release provided by Stanford University.

Source: www.sci.news