These days, even niche industries are concerned about people seeking greener material and process options, from washing machine waste to synthetic wool. ring glove uses laminates (thin layers of wood or other materials) with carbon-negative options that they claim will improve performance while still looking the same.

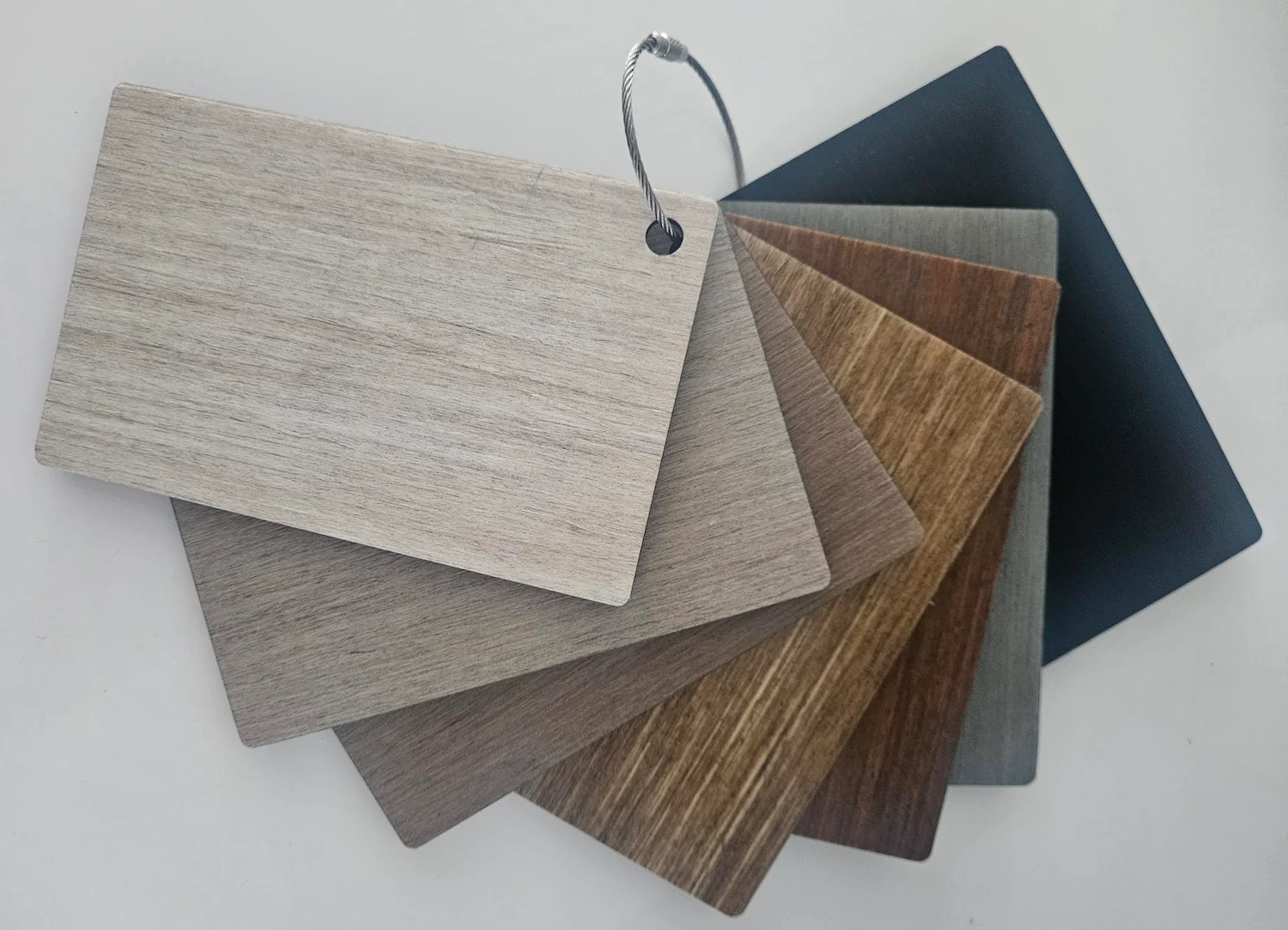

Laminate or veneer is common in every home and car. These are thin decorative pieces of wood that are placed over the molded or printed bodies of dashboards, appliances, and even home trim. It’s everywhere, but unfortunately, it’s not always sustainably sourced or manufactured.

Lingrove has developed an alternative to wood veneer from flax fibers and plant-based resins. This will be a material that is carbon negative yet has “very high stiffness, durability, and durability,” meaning it will be better for feel, temperature, and other materials (such as coffee). ). They call it “ekoa” (yes, in lowercase) and hope to expand into cars and other interior surfaces with a new $10 million funding round.

The Series B round was led by Lewis & Clark Agrifood and Diamond Edge Ventures, with participation from Bunge Ventures and SOSV.

The company claims that its materials are not only environmentally friendly and comparable or better in terms of strength etc., but can also have a positive impact on indoor air quality. Recycled plastics and other repurposed materials are often used for things like cabinetry and trim, but such surfaces often lack the desired appearance, hardness, and other qualities, and in some cases, There can be quite a bit of fumes (that’s the “new car smell”). ).

Image credits: ring glove

“We have healthy air, low carbon, high performance and beautiful products,” said CEO Joe Luttwak. “The use of industrial raw materials can be environmentally beneficial in some cases. However, many of their byproducts still emit VOCs. [volatile organic compounds] These negatively impact indoor air quality and cannot produce high-performance materials. ”

ekoa material has excellent performance, does not allow strange gases to seep into your kitchen or car cabin, and looks almost the same as regular wood. It can be fine-tuned to have different shades and opacity, has all the benefits of engineered laminates while generally being carbon negative, and can be crushed and reused when disposed of.

Image credits: ring glove

You may be wondering, like I did, why not just use real wood, i.e. things like sawdust and wood chips that already come out of the industrial wood treatment process. According to Luttwak, these are perfectly good structural materials, the ones in the center of the board, but they are not decorative. There’s a reason things like MDF boards tend to have at least one side covered in veneer. The interior wood glue mixture is unappealing and not particularly resistant to solvents, oils, etc.

Veneers aren’t the hottest or most exciting business to work on, but innovation is happening in a corner of the industry where smart alternatives can scale up to millions of products and at least reduce waste a little. It’s always reassuring to see that.

The new investment should help the startup go from small-scale in-house manufacturing to fulfilling all pre-orders and expanding into the automotive world.

Source: techcrunch.com