Researchers test batteries using new materials designed by AI

Microsoft's Dan DeLong

Artificial intelligence can accelerate the process of discovering and testing new materials, and researchers have used that ability to develop batteries that are less dependent on the expensive mineral lithium.

Lithium-ion batteries power not only electric cars but also many devices we use every day. They will also become a necessary part of green power grids, as batteries will be needed to store renewable energy from wind turbines and solar panels. However, lithium is expensive and mining it damages the environment. Finding a replacement for this important metal can be expensive and time-consuming, requiring researchers to develop and test millions of candidates over years. Utilizing AI, nathan baker Microsoft and its colleagues accomplished this task in a few months. They designed and manufactured a battery that uses up to 70% less lithium than some competing designs.

The researchers focused on types of batteries that contain only solid parts, looking for new materials for battery components called electrolytes, through which charge is transferred. They started with 23.6 million candidate materials, designed by tweaking the structure of an established electrolyte and replacing some lithium atoms with other elements. The AI algorithm filtered out materials that were calculated to be unstable or have weak chemical reactions that make the battery work. The researchers also considered how each material behaved when the battery was actively operating. After just a few days, their list contained just a few hundred candidates, some of whom had never been studied before.

“But we're not materials scientists,” Baker says. “So I called the experts who have worked on large-scale battery projects at the Department of Energy and said, 'What do you think? Are we crazy?'

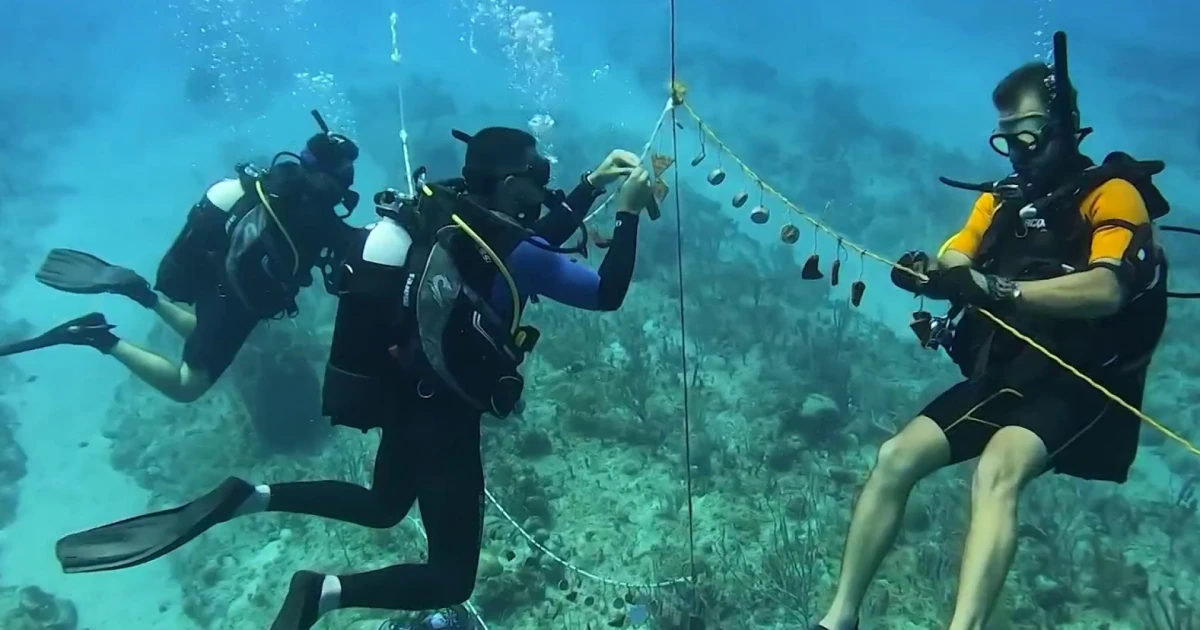

vijay murugesan He works at the Pacific Northwest National Laboratory in Washington state and was one of the scientists who answered the phone. He and his colleagues proposed additional screening criteria for AI. After further rounds of elimination, Murugesan's team finally selected one of his AI proposals and synthesized it in the lab. It was noticeable because half of what Murugesan expected to be lithium atoms were replaced with sodium. This is a very novel recipe for an electrolyte, he said, and the combination of the two elements raises questions about the fundamental physics of how the material works in batteries. Masu.

His team built a working battery using this material, albeit with a lower conductivity than similar prototypes that use more lithium. Both Baker and Murugesan said much work remains to optimize the new batteries. However, the manufacturing process took about nine months, from the time Murugesan first talked to his Microsoft team until the battery was functional enough to light a light bulb.

“The methodology here is cutting edge in terms of machine learning tools, but what really elevates this is that things have been created and tested,” he says. Rafael Gomez-Bombarelli from the Massachusetts Institute of Technology was not involved in this project. “It's very easy to make predictions. It's hard to convince someone to invest in an actual experiment.” He said the team will accelerate calculations that physicists have been making for decades, and It is said that AI was used to strengthen it. However, this approach may also encounter obstacles in the future. For this kind of work, he said, the data needed to train the AI is often sparse, and materials other than battery components may require more complex ways of combining elements. he says.

topic:

Source: www.newscientist.com