As reported in nature communications, a collaborative international effort led to the creation of the first mid-infrared supermirror with extraordinary reflectivity. This innovation promises to significantly enhance environmental gas sensing and industrial processes, and represents a major leap forward in mirror technology.

Advanced infrared mirrors enhance climate and biofuels research through precise trace gas detection. An international research team from the United States, Austria, and Switzerland has demonstrated the first true supermirror in the mid-infrared spectral region. These mirrors are key to many applications, including optical spectroscopy for environmental sensing and laser cutting and welding for manufacturing.

Achieving near-perfect reflectance. In the field of high-performance mirrors, everyone is searching for the impossible: a perfectly reflective coating. In the visible wavelength range (i.e. between 380 nm and 700 nm), advanced metal mirrors achieve reflectivity as high as 99%. This means 1. photon 99 is lost with each reflection.

Although this may be impressive, in the near-infrared region (i.e., between approximately 780 nm and 2.5 μm), mirror coatings demonstrate a reflectance of 99.9997%, meaning that out of 1 million reflected photons, only one photon is lost. There are only three.

There has been a long-standing desire to extend the performance level of this supermirror into the mid-infrared (wavelengths from 2.5 μm to 10 μm and beyond), where it could enable advances in trace gas sensing tasks related to climate change and biofuels. Become. It can also be used in industrial applications such as laser processing and nanofabrication. So far, the best mid-infrared mirrors lose one photon to approximately 10,000 photons. This is about 33 times worse than near-infrared mirrors.

International cooperation leads to breakthroughs. As explained in the article published in nature communications, Thorlabs’ Crystalline Solutions (Santa Barbara, California), the Christian Doppler Institute for Mid-Infrared Spectroscopy at the University of Vienna (Austria), the US National Institute of Standards and Technology (NIST), and the University of Neuchâtel (Switzerland) are the first to create a truly intermediate We have demonstrated an infrared super mirror.

These mirrors lose only 8 out of 1 million photons and achieve a reflectance of 99.99923%. Achieving such extreme reflectance required a combination of mastery of materials, mirror design, and manufacturing processes.

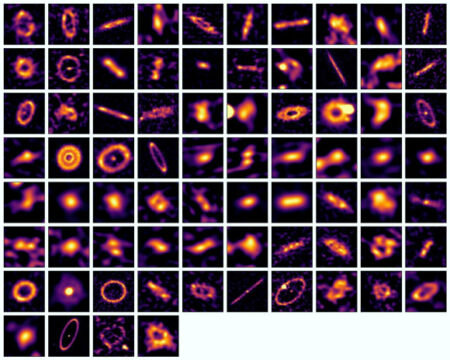

Patterned 4-inch GaAs wafer with single-crystal GaAs/AlGaAs die. The final product is fused onto a coated silicon substrate. Credit: George Winkler A new paradigm for mirror coatings. To realize this first-generation mid-infrared (MIR) supermirror, researchers devised and demonstrated a new paradigm in coatings. They combined traditional thin-film coating techniques with new semiconductor materials and methods to overcome material limitations in the challenging mid-infrared region.

Garrett Cole, technical manager for our crystal solutions team, said: By extending this platform to longer wavelengths, our international collaboration has demonstrated for the first time a MIR coating method with less than 5 ppm of undesired absorption and scattering losses. ”

These mirrors utilize the extremely high purity and superior structural quality of molecular beam epitaxy, an advanced process used to fabricate many different semiconductor devices, to produce single-crystal GaAs/AlGaAs with negligible absorption and scattering. Produces multilayer films. This starting material is processed into high-performance mirrors using advanced microfabrication techniques, including direct “fusion” bonding onto high-quality conventional amorphous thin-film interference coatings deposited at the University of Neuchâtel.

Manufacturing these revolutionary mirrors was only half the challenge. Scientists also needed to systematically measure the mirrors to prove their superior performance. Gar-Wing Truong, principal scientist at Thorlabs Crystalline Solutions, said: “It was a huge team effort to bring together our equipment and expertise to clearly demonstrate total losses as low as 7.7ppm, six times higher than previously achieved by any of his traditional MIR coating techniques will do. ”

Co-lead author Lukas Perner, a scientist at the University of Vienna, added: Our combined efforts in innovative mirror technology and advanced characterization methods have enabled us to demonstrate superior performance and break new ground in MIR. ”

Impact on environmental sensing and spectroscopy. The immediate application of these new MIR supermirrors is to significantly improve the sensitivity of optical devices used for measuring trace gases. These devices, called cavity ring-down spectrometers (CRDS), can detect and quantify trace amounts of important environmental markers, such as carbon monoxide.

The research team turned to NIST research chemists Adam Fleischer and Michelle Bailey, who have been working on this technology for years. In a proof-of-concept experiment that put these mirrors through their paces, Fleischer and Bailey showed that the mirrors were already superior to the state-of-the-art.

“Low-loss mirrors make it possible to achieve very long optical path lengths in small devices, in this case like compressing the distance from Philadelphia to New York City to a one-meter range,” says Bailey. says Mr. “This is an important advantage for ultrasensitive spectroscopy in the mid-infrared spectral range, such as the measurement of radioisotopes important for nuclear forensics and carbon dating.”

Reference: “Mid-infrared supermirror with finesse greater than 400,000” Gar-Wing Truong, Lukas W. Perner, D. Michelle Bailey, Georg Winkler, Seth B. Cataño-Lopez, Valentin J. Wittwer, Thomas Südmeyer, Catherine Nguyen, Author David Folman, Adam J. Fleischer, Oliver H. Heckle, Garrett D. Cole, December 6, 2023, nature communications. DOI: 10.1038/s41467-023-43367-z

(function(d, s, id){ var js, fjs = d.getElementsByTagName(s)[0]; if (d.getElementById(id)) return; js = d.createElement(s); js.id = id; js.src = “//connect.facebook.net/en_US/sdk.js#xfbml=1&version=v2.6”; fjs.parentNode.insertBefore(js, fjs); }(document, ‘script’, ‘facebook-jssdk’));

Source: scitechdaily.com