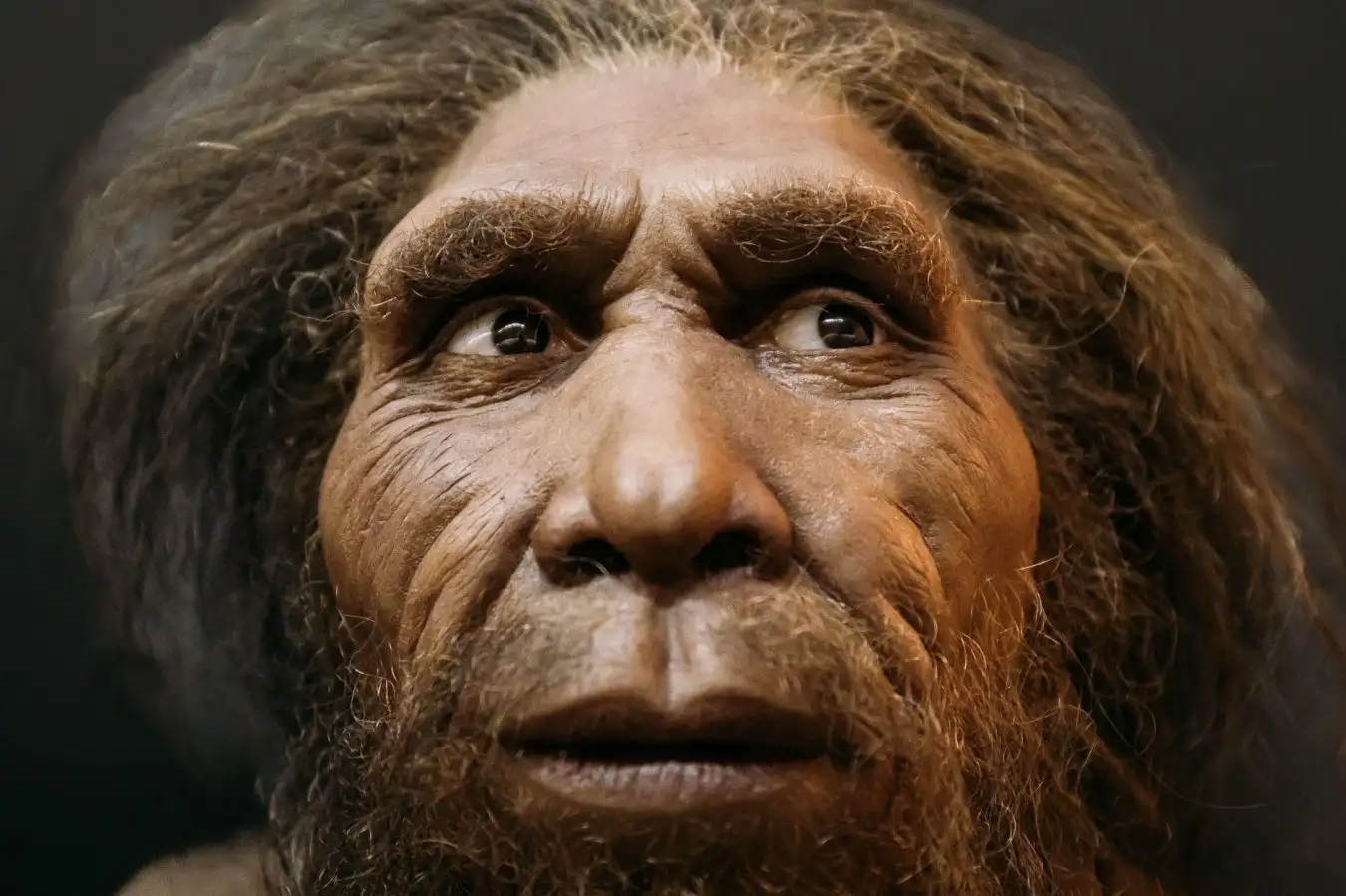

Farmers rely on ammonia to fertilize their crops.

Patty Calfee/Getty Images

The environmentally friendly technology uses multi-chamber chemical reactors to turn wastewater into ammonia and harmless by-products. This sustainable alternative requires much less energy than traditional methods to produce this important chemical.

Hundreds of millions of tons of ammonia are used every year in industries such as agriculture, refrigeration systems, paper and cleaning products. Producing this amount of chemical uses about 2% of total energy consumption and accounts for 1.4% of global carbon dioxide emissions.

Part of this environmental cost comes from traditional ammonia production methods, which require high temperatures and pressures. To make ammonia production more sustainable, Fengyan Chen Researchers at Rice University in Texas hoped to translate that technology into a room-temperature reactor.

Their reactor takes in water laced with nitrates, a nitrogen compound commonly found in wastewater, such as industrial or agricultural runoff contaminated with nitrogen fertilizers. When the nitrate water enters the first of three chambers, electrodes, like those found in a battery, create an electrochemical reaction that turns the liquid into its three components. Only ammonia remains in the reactor’s first chamber, purified water flows out of the second chamber, and oxygen flows into the third.

Because ammonia contains only nitrogen and hydrogen, the electrochemical reaction requires no other components than wastewater, and the purified water produced is clean enough to meet World Health Organization (WHO) regulations for drinking water.

Similar reactors have been tested before, Chen says, but the electrodes couldn’t shuffle charges at a high enough voltage for the reaction to work unless the wastewater was mixed with large amounts of salt. Chen and his colleagues made the device more practical by filling the central chamber with a porous material that acts as the salt, allowing wastewater to be fed directly into the reactor without any additives.

In tests using water samples with realistic nitrate concentrations, the reactor processed 100 milliliters in about one hour and continued to operate without problems for 10 days straight. The performance of this reactor is comparable to previous, more complex reactor designs.

Chen says the team only tested the reactor in the lab using nitrate-rich water, not actual wastewater samples that contain more than just nitrates, but the researchers envision local businesses and farms eventually using the reactors to recycle their wastewater, rather than sending it to faraway treatment facilities where it would waste its ammonia-producing potential.

In the best case scenario, the farm would have its own solar- or wind-powered reactor. Farmers would run local wastewater through the device, which would immediately Reusing ammonia It is mined for fuel and fertilizer.

“It’s still at the academic research level, but this is my ultimate dream,” Chen says.

topic:

- Chemical /

- Sustainability

Source: www.newscientist.com