Like it or not, the leather industry is a major contributor to greenhouse gas (GHG) emissions and global waste generation. Current methods being used to meet the increasing demand for leather involve very simple and completely unsustainable solutions. It is simply raising more livestock (this is 14% of global greenhouse gas emissions).

But now there are startups leading the way in developing bio-based alternatives that have properties similar to, or even better than, traditional leather.

Alternative leather startup gelatex To date, we have raised $1.3 million from Estonia. Based in Copenhagen, Beyond leather We produce plant-based, eco-friendly alternatives to animal leather. It has raised 1.2 million euros so far.

Vitro Lab The San Jose-based company has raised $54.4 million and is developing a platform to make leather using stem cell-based technology. Meanwhile, modern meadow is working on lab-grown leather (among other materials) and has raised $183.6 million.

As you can see, there is a lot of interest in this area.

Now, a startup originally from Turkey and now based in San Francisco thinks it has come up with a game-changing product.

Gozen has now raised $3.3 million in a seed funding round led by Happiness Capital (lead investor) with participation from Accelr8, Astor Management, and Valley-based SOSV. The company is currently planning a facility in Turkey with a production capacity of up to 1 million square feet.

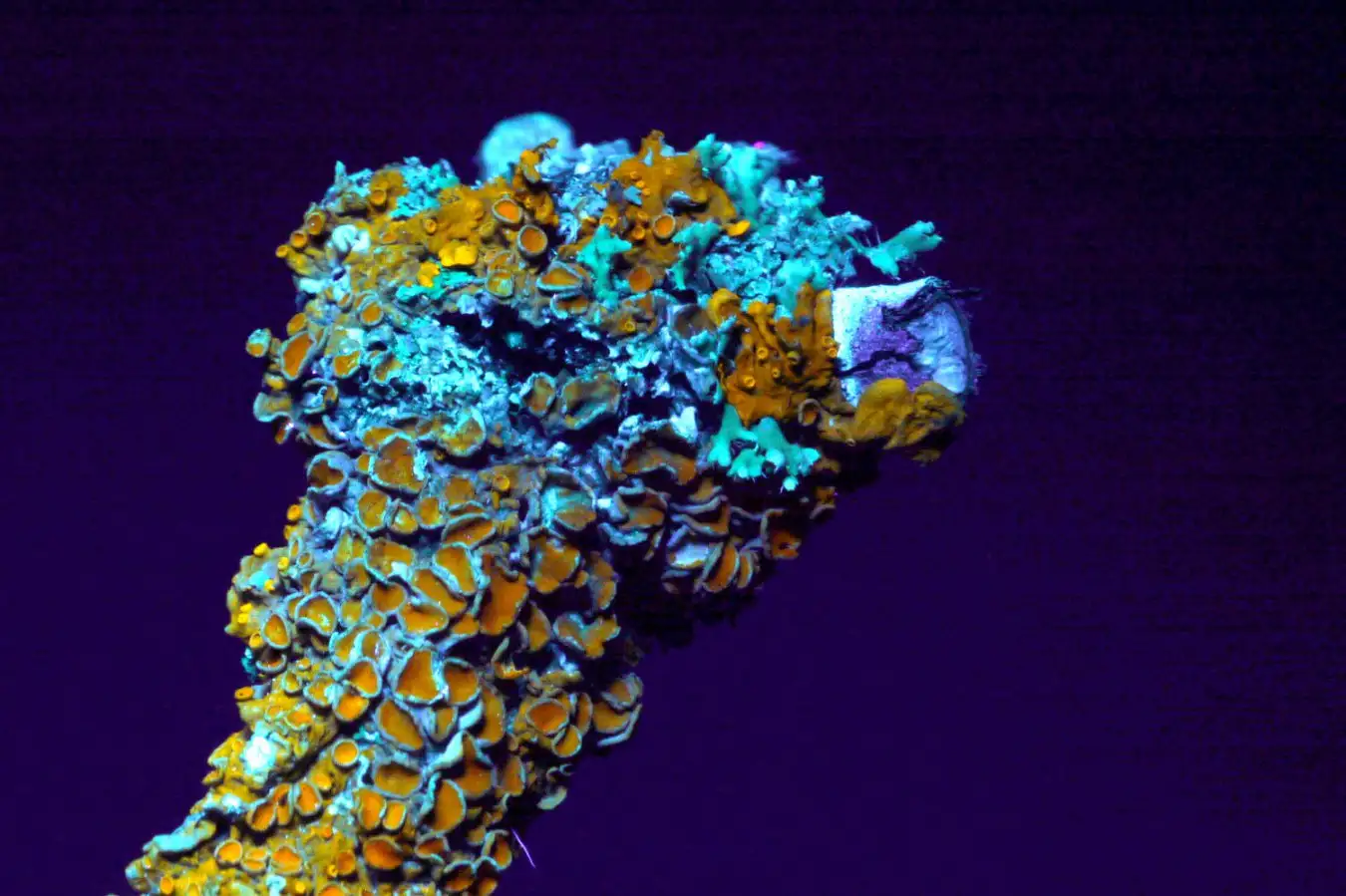

The startup’s biomaterial Lunaform is vegan, plastic-free, and produced by microorganisms during the fermentation process. The material is intended for use in the fashion and automotive industries, and the company has patented the technology in Turkey and is applying for patents in other countries.

The material was unveiled at the Balenciaga Summer 24 show during Paris Fashion Week earlier last month.

Gozen said Lunaform is a unique, fully formed material that ultimately provides increased strength and flexibility. (Using multiple layers of plant-based composite leather makes it more susceptible to damage). With customizable thickness and texture, he can be produced in 13 square foot sheets.

Ese Gozen, founder and CEO of GOZEN, told me over the phone: We use a fermentation transplantation system that creates the material in just 10 days. Now that the formulation is solid, it’s time to harvest it. This is microbial cellulose, which is another type of cellulose. ”

She said the resulting material was “very strong and very thin.” The current material is 0.2mm, giving it a unique texture. Contains no plastic or toxic chemicals. ”

He added that he has a startup plan that aims not only for fashion but also for the automobile industry.

Poe Bronson, managing director of SOSV IndieBio, Gozen’s first investor, added in a statement: However, I believed that your approach could outperform other approaches in both performance and economy. ”

No matter what happens, the market is growing.

The global leather products market size is projected It is expected to grow from $468.49 billion in 2023 to $738.61 billion by 2030 at a CAGR of 6.7%.

Source: techcrunch.com