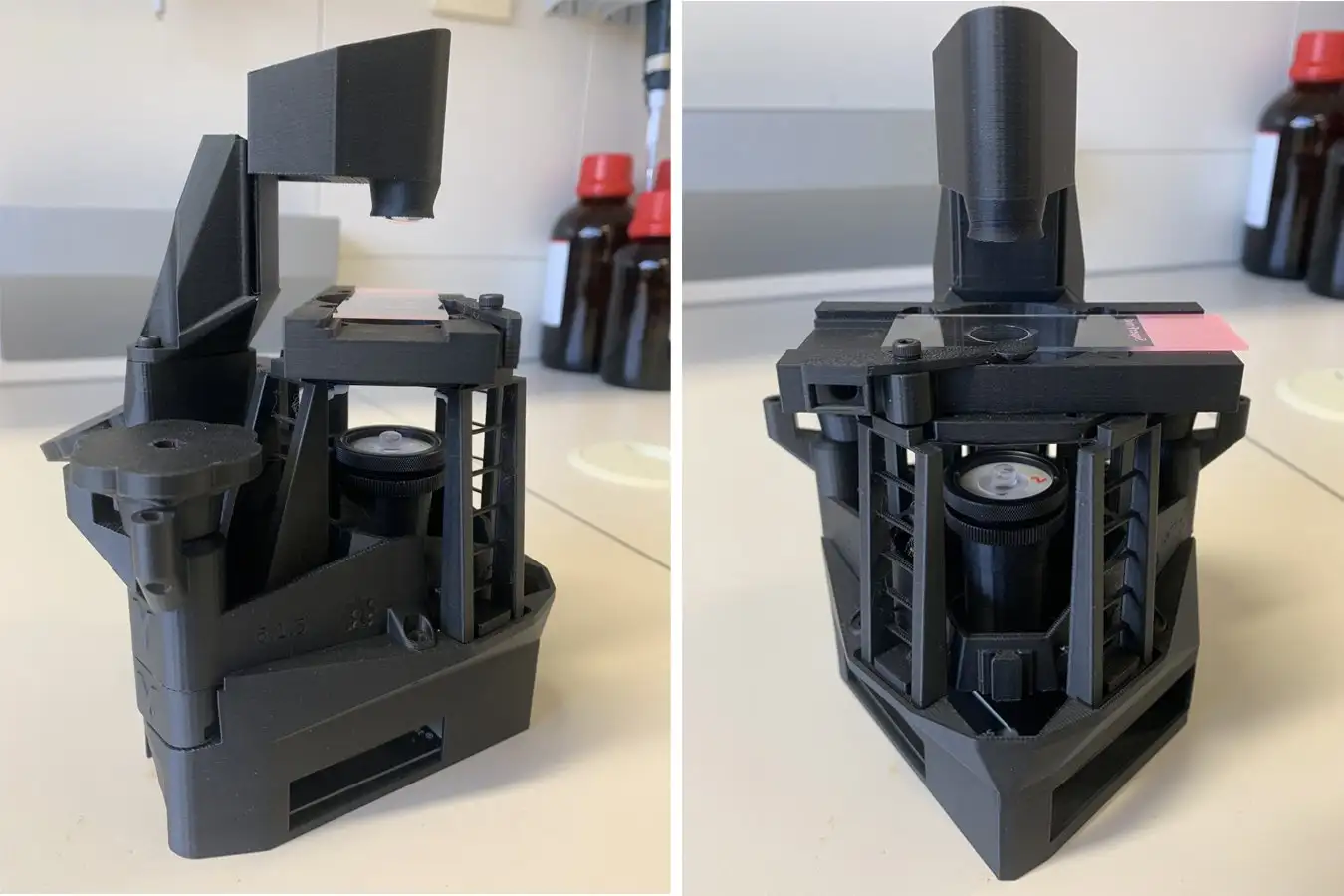

3D Printed Microscope Dr. Liam M. Rooney/University of Strathclyde

In early 2025, a groundbreaking paper revealed the world’s first fully 3D printed microscope, sparking significant enthusiasm among researchers. This innovative microscope can be constructed in just a few hours and costs significantly less than traditional models.

Dr. Liam Rooney, a professor at the University of Glasgow involved in this project, stated to New Scientist that coverage of the microscope has prompted outreach from biomedical researchers, community organizations, and filmmakers worldwide. “The community response has been amazing,” he noted. The research has been subsequently published in Microscope Journal.

His team utilized the OpenFlexure design, a publicly available resource for creating scientific instruments via 3D printing. Additionally, they incorporated a commercially available camera and light source, all controlled by a Raspberry Pi computer.

A major breakthrough was the 3D printing of microscope lenses using clear plastic, significantly reducing costs and making microscopy more accessible. While traditional microscopes can cost thousands, this new version is available for under £50.

Since January, the team has produced approximately 1,000 lenses in various shapes, according to Gail McConnell from the University of Strathclyde, UK.

Several companies manufacturing products requiring lenses have shown interest in the team’s research, as inexpensive, lightweight 3D-printed lenses are rare in large-scale production. They tested the microscope on blood samples and thin sections of mouse kidneys, confirming its potential utility in medical and biological research.

The team’s mission is to democratize access to microscopy. They are collaborating with the Kwame Nkrumah University of Science and Technology in Ghana, aiming to enhance microscope accessibility for researchers and students in West Africa. They have also secured funding from the UK Institute for Technology Strategy and participate in initiatives that empower students facing educational barriers.

In addition, they have developed a new microscope course at the Strathclyde Light Microscopy Course, tailored for researchers of all experience levels. Mr. Rooney emphasized, “This is truly changing how we educate.”

Furthermore, researchers believe there’s ample opportunity for improvement. They are focused on enhancing resolution without adding costs, having already improved contrast by up to 67%.

McConnell remarked that because the microscope is designed for low-cost consumer electronics and accessible 3D printers, its future scalability is tied to advancements in 3D printing technology. “As these printers improve, so will we. The bottleneck isn’t imagination,” she explained. “We are continually receiving inquiries to develop new innovations.”

Topics:

- 3D Printing/

- 2025 News Review

Source: www.newscientist.com