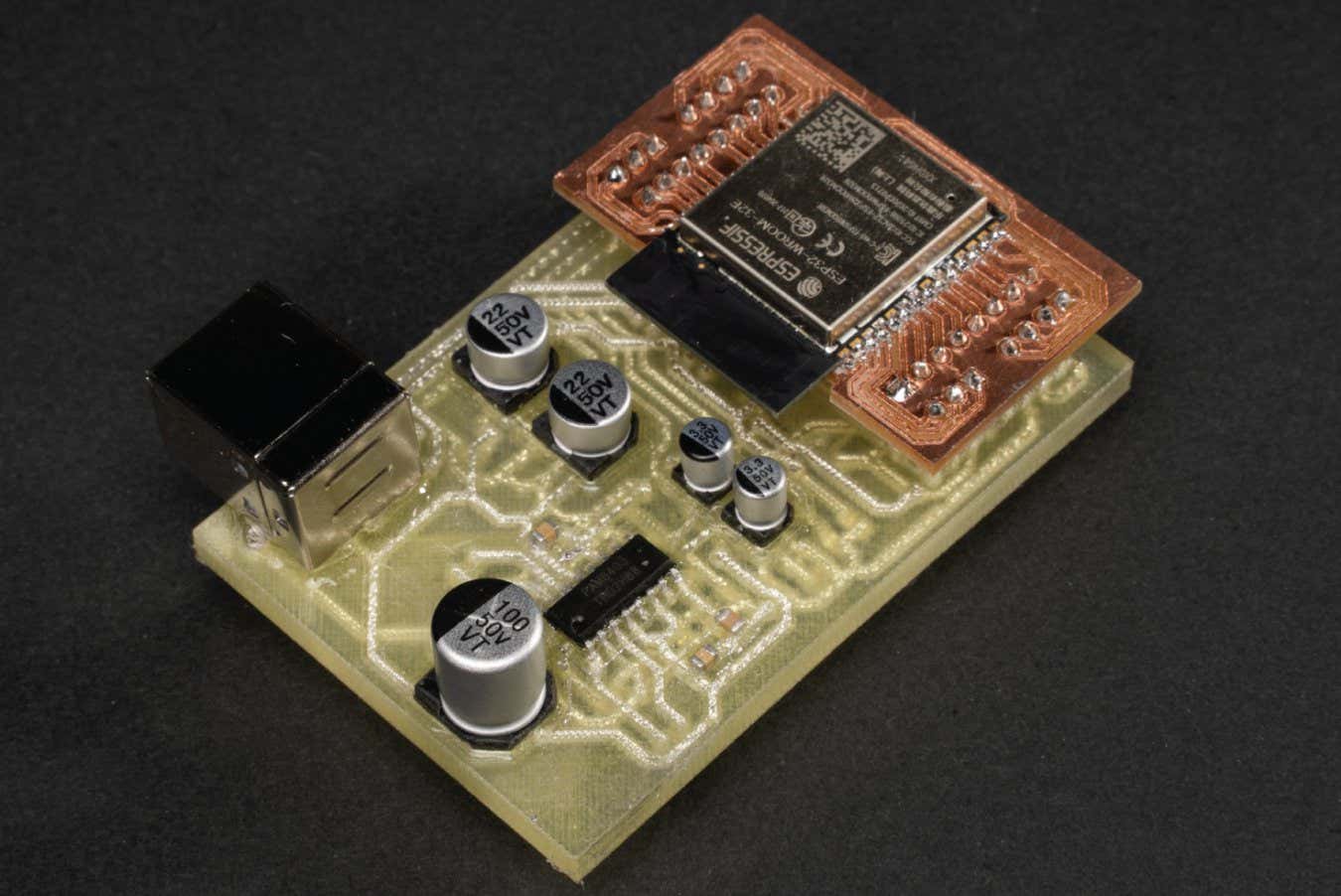

Prototype electronics can be made from polymers that dissolve in water, facilitating recycling.

ZEYU YAN/University of Maryland

Devices like Bluetooth speakers can be 3D printed using water-soluble materials in just a few hours. This innovation enables rapid prototyping, easier recycling of electronic waste, and encourages more sustainable manufacturing practices for consumer electronics.

Researchers have successfully created technology that can dissolve, including printed circuit boards that house essential components and wiring for modern electronics. Each year, hundreds of millions of printed circuit boards are produced for military aircraft, automobiles, medical devices, smartphones, and inexpensive toys. Yet, globally, only a fraction of these devices are recycled through labor-intensive methods, often involving shredding to reclaim usable materials, according to Huaishu Peng from the University of Maryland.

Peng and his team crafted a 3D printed circuit board with polyvinyl alcohol, a polymer that dissolves in water. They filled the circuit board’s channels with liquid gallium-indium metal alloys for wiring, and manually attached electronic components. After sealing the circuit with a polymer adhesive, the device was dried for an hour at 60 °C.

This method enabled researchers to assemble functioning prototypes of a Bluetooth speaker, a fidget toy, and an electronic gripper with three fingers. A small amount of water does not immediately damage these devices, but after soaking for 36 hours at a room temperature of 22°C, they dissolve.

The researchers could then easily retrieve most electronic components and liquid metals, which accumulated as small beads. The evaporation of water also allowed them to recover 99% of the dissolved polyvinyl alcohol.

Soluble circuit boards are particularly beneficial for designers who aim to quickly test and validate electronic prototypes, as recycling traditional printed circuit boards presents significant challenges. As noted by Jasmine Lu from the University of Chicago, Illinois, in her study on circuit board reuse, “Printed circuit boards are a major source of e-waste during the prototyping of electronic devices.”

A 2022 United Nations Report regarding e-waste revealed that Asia generated 600,000 tons of discarded circuit boards but managed to recycle only 17%. In contrast, Europe and North America produced 300,000 tons of printed circuit boards, achieving a recycling rate of 61% in Europe and 44% in North America.

What sets this approach apart is that virtually anyone with a 3D printer can implement this dissolvable electronics methodology, making it more accessible compared to other sustainable electronics initiatives, according to Lu. For practical use, Peng suggests that the devices can be safeguarded with a temporary waterproof casing.

Nonetheless, due to the inherent fragility of these circuit boards, Lu indicates that soluble electronics are currently more suited for rapid prototyping rather than mass production of finished electronic goods.

Peng and his colleagues have not dismissed the idea of mass production. They are reaching out to circuit board manufacturers to explore the possibilities. For now, Peng aims to utilize this technology to enable university students to rapidly prototype and reuse designs.

“Typically, you would need to outsource circuit board production to a factory, which could take weeks for manufacturing and shipping,” he explains. “You can design something here, print it in under 30 minutes, and if it doesn’t work, simply dissolve it in water and try again.”

topic:

Source: www.newscientist.com